A better way of doing tyres

Progress – at least, in my head – continues at a good pace. We’re on track for being able to test & tune the robot at Extreme Robots Manchester, complete with weapon. However, a big sticking point on the build has been a rather simple one.

Tyres.

I thought I was going great – the mould that Gary (PP3D) printed was excellent and looked the bushiness.

However, there was a fundamental problem in the design that I had not accounted for – pointy-outy bits! More on that later.

We got to the workshop and quickly set about putting a wheel blank into the mould, which went about as well as a fish going for a nice swim in a hurricane. Two precision engineers had made the mould and wheel blank, and due to my own silliness, had done it exactly to the drawings. This meant that something had to give – so the centre of the wheel mould was broken off and the wheel blank forced in with a hammer.

Next up was the Shore 50 rubber – an ebay special – which was great! Sticky, pliable, easy to pour…. and needed to be set with the help of a handy Aga nearby. Fast forward a couple of hours. We couldn’t get the wheel out due to the aforementioned pointy-outy bits! And so, with darkness fast approaching, Chris said he’d get it out in the morning:

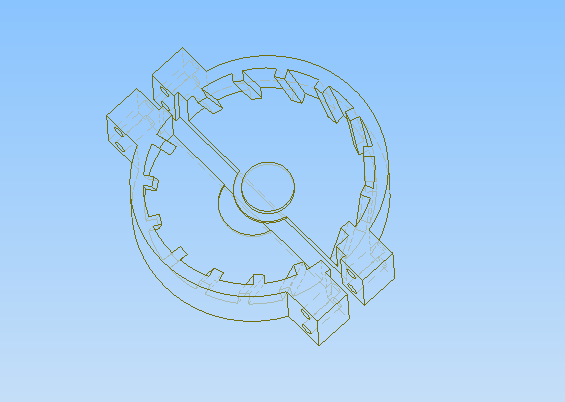

True to his word, Chris did indeed get the wheel out, but had to break the mould in the process. It also came about that the Shore 50 rubber was a little too pliable and came off the tyre without much effort. As a result of what we’ve learned through the process, I have now designed a slightly better 2-part mould (see below) and we’re switching up the rubber compound – a trade off of less stickiness but more durability.

The tyres are aruguably the most imporant part of the robot itself, and as such we’re going to a combat-proven tyre compound, Devcon Flexane 60.

Until Next Time

Until Next Time

Rob

(And if you’re thinking – Hey! You’ve just nicked that from Spectre – 幽灵! Yes, yes I have. )